We're hiring! Visit the Careers page to view openings.

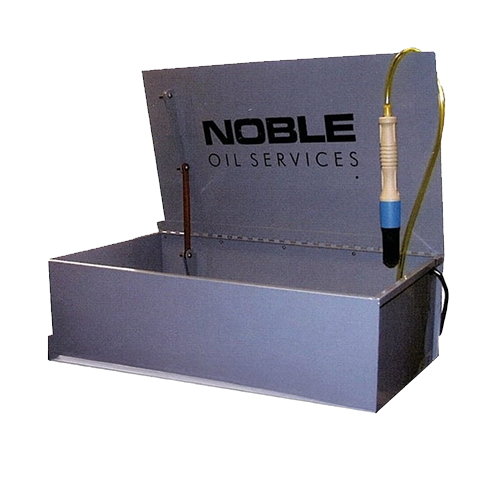

Parts Washer Service

Parts Washer Service

Authorized Dealer for CUDA Parts Washers

Noble Oil Services is a proud distributor of industry-leading CUDA aqueous parts washers. Many of our customers have already switched from the old sink-on-a-drum, solvent based systems to a detergent based aqueous washer, allowing for cleaning and leading to cost and time savings. In other words, they get cleaner parts and save money!

Here’s how. The national average for washing parts is one-half hour per day for every technician. Most repair shops charge $65 to $150 per hour for a technician’s services. That means that a half hour of cleaning parts could be costing your business $30 to $75 per day—or $7,800 to $19,500 per year —in billable repair time that’s not being used (based on 260 work days per year, or 2,080 hours). This doesn’t even include the cost of solvent disposal for the old sink-on-a-drum method.

You can easily see that it doesn’t take long to recoup the total cost of an industrial parts washer with the additional revenue you can generate by renting a CUDA.

Aqueous parts washers clean faster and better without using harmful solvents!

CUDA automatic parts washers provide a safe and efficient solution to cleaning parts because they don’t use harmful cleaning solvents. Our automatic parts washers also provide a time-saving, easy parts cleaning solution for your staff, allowing them to clean parts while simultaneously performing other tasks.

Contact Noble Oil Services today to learn more about our parts washer rental program. You’ll be happy that you did! Save money and time. Plus, get your parts and tools cleaner than ever!

Click on a model below to learn more

Aqueous Parts Washers

Solvent Parts Washers

Why choose Noble Oil Services Parts Washer service?

Flexibility

Machines may be purchased or leased depending on customer preference. Noble Oil Services offers both solvent-based and aqueous-based solutions. We customize a program that meets YOUR needs.

New Cleaning Solution

Noble Oil Services provides ONLY brand new machine-specific M2 solvent or detergent for every service, thus ensuring the safety and effectiveness of the units.

Service

Our service has many unique aspects designed to meet the specific needs of your operation. Our highly trained service technicians thoroughly clean each unit before adding the new cleaning agent.

Testing

Noble Oil Services uses a cost effective analytical testing protocol to ensure the proper disposal or recycling of the spent solvent or solution. Following receipt of analytical testing results, a waste profile is created using our proprietary database program.

Compliance

All spent materials are recovered for recycling and disposal in accordance with all local, state, and federal regulations. Our program is specifically designed to generate less paperwork, reduce regulatory reporting, and decrease our customers’ liability.

Responsibility

As with all of our services, we strive to develop environmentally sensible solutions. Used solvent is recycled into a product for the roofing industry, and aqueous solution is treated with our other oily water materials.

Schedule a pick up today.

Click the button on the right to call us.